3D printing issues

10 Jun 2024

Here I will document all issues and settings for my Ender3v3KE printer.

I’ve worked with 3D printing during my internship, but I wanted my own printer so I could experiment and tinker with it without possibly breaking someone elses printer. My printer is very different than the Prusa MK3 I’ve learned to print with, and Ender is known for being more difficult and needing some more love. Except for having to tighten my belts when my printer arrived, I haven’t had any big issues (yet).

Buildplate adhesion

Issue: A couple of prints have failed because they came loose from the build plate during printing. To try and fix this I’m experimenting with different build plate adhesion settings.

I’m printing a Benchy but on 50% scale

Filament: Hyper PLA (Creality) Slicer settings: Creality Print Printer - Ender-3 V3 KE_0.4 nozzle Material - Hyper PLA_1.75 Parameter config - High Quality 0.10mm

Extra settings: Build plate adhesion type - Raft

Printing with TPU

Issue: I’ve bought some TPU filament. TPU is a flex material, and this specific filament (Sunlu TPU Silk Burgundy 1.75mm) is strength A95 (about as flexible as a tire of a toy car).

I’ve never printed with TPU before, and it needs different settings compared to PLA so I’m going to experiment a bit to figure out what works. TPU is also a hygroscopic, which means it will absorb water. Drying the filament is suggested.

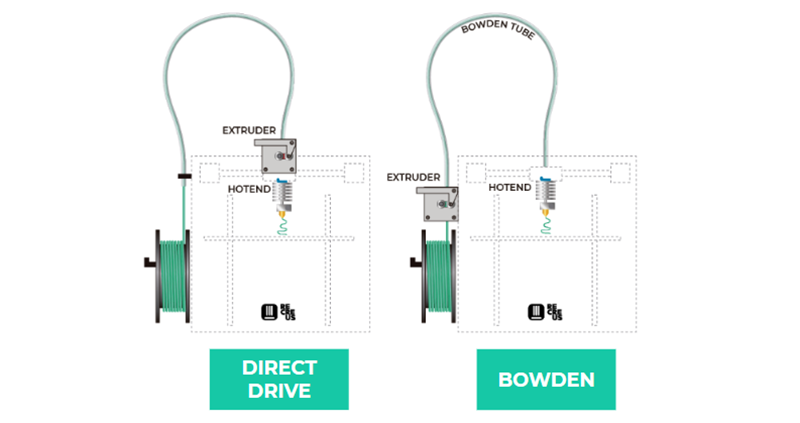

TPU’s flexibility makes it harder to properly extrude the filament without causing nozzle jams, especially for printers with a Bowden extruder. I looked up the specs of my printer and I have a direct drive extruder.

I’m printing a Benchy but on 50% scale

Filament: TPU Silk Burgundy (Sunlu) Slicer settings: Creality Print Printer - Ender-3 V3 KE_0.4 nozzle Material - Generic-TPU_1.75 Parameter config - Normal 0.20mm

I’ll start with the Generic-TPU setting in Creality print without changing any values. I expect this to fail miserably.

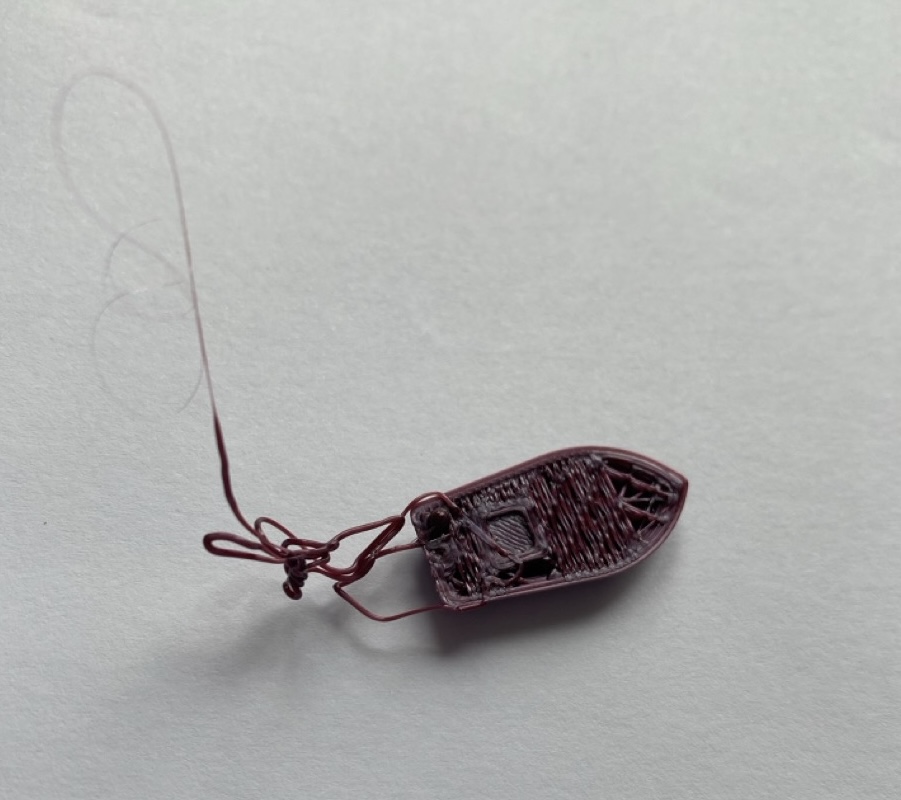

Print #1

It went better than expected. The lines on the side are very clean. After 3 min of printing, the model came loose from the bed, but I’ve had the same problem with PLA prints, and was able to solve this by adding a brim.

It went better than expected. The lines on the side are very clean. After 3 min of printing, the model came loose from the bed, but I’ve had the same problem with PLA prints, and was able to solve this by adding a brim.

For the next print I’ll add a brim and try again.

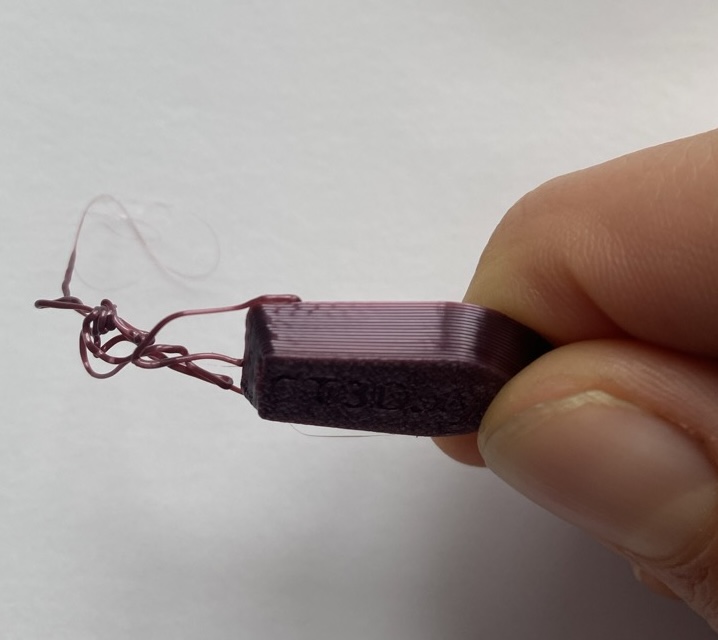

Print #2 Extra settings: Build plate adhesion type - Raft

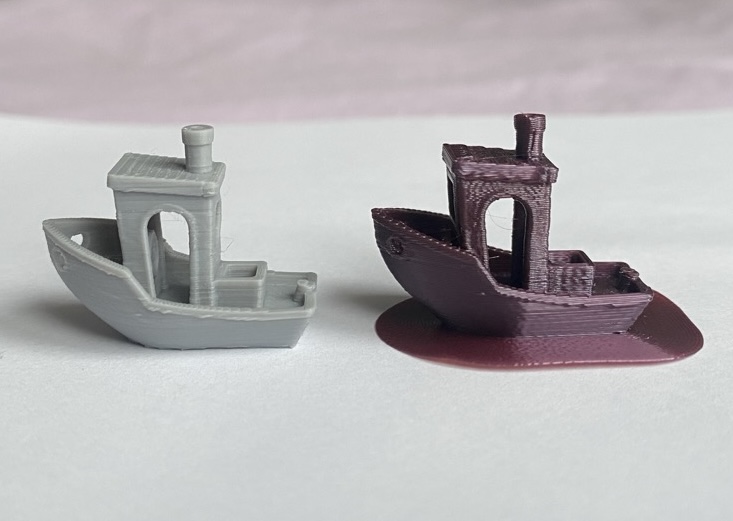

I’m impressed. There is a tiny bit of stringing on the inside, but aside from that the print is very clean. The grey benchy is PLA printed with a high quality parameter config (layer height 0.10) so it’s not a completely fair comparison but side to side I don’t see any obvious differences. I do want to see what a 0.10mm layer hight looks like.

Print #3 Parameter config - High Quality 0.10mm

Slicer

Ender comes with it’s own slicer, Creality Print, and apart from being able to remotely send my g-code and start my printer, I dislike Creality Print. Online I read it’s one of the worst slicers, personally I didn’t experience any big obstacles yet, but the software is not native compatible with macbooks with a M1 chip (I use a Macbook pro 2019 with M1) which gives me the wrong resolution. I’ve worked with PrusaSlicer during my internship, and I prefer how PrusaSlicer clearly shows which settings are simple, advanced or expert settings and also shows which settings have been changed. Prusa has profiles for non-Prusa printers, but sadly not for the Ender 3 V3 KE.

Eventually I want to be able to make my own profile, but after watching a bit of a Youtube tutorial on how to make a profile for a custom build printer I decided I’m not there yet. Lucky for me other people made a profile for the Ender 3 V3 KE in PrusaSlicer and were kind enough to share this. I installed the profile, but while reading up on PrusaSlicer for the Ender 3 V3 KE, I ran into a lot of positive comments on Orca Slicer. Apparently Orca had support for my printer, and also LAN printing options.